COMPREHENSIVE GUIDE

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, are versatile containers used for storing and transporting a wide range of materials. They are designed to maximize efficiency and safety in material handling operations. This guide will provide an in-depth look at the various aspects of FIBC bulk bags, from their construction to their applications in different industries.

Other names for Bulk bags include FIBCs (Flexible Intermediate Bulk Containers), jumbo bags, big bags, and super sacks.

Choosing the right FIBC (Flexible Intermediate Bulk Container) for your application is essential for maximizing efficiency and safety in material handling operations. Understanding the different types of bulk bag constructions can help you make an informed decision that best suits your needs.

FIBCs are available in various construction types, each offering unique benefits depending on the intended use and the nature of the material being transported or stored. Here are the main types of FIBC constructions:

U-Panel Bags

Construction: U-panel bags are made from three body panels: one continuous piece that forms the bottom and two sides, and two additional pieces that form the remaining sides.

Advantages:

-

Durability: U-panel bags are known for their strength and durability. The design distributes weight evenly, making them ideal for carrying heavy loads.

-

Shape Retention: These bags maintain a relatively square shape when filled, which helps in stacking and storage.

Applications:

-

Suitable for a wide range of materials, including grains, minerals, and chemicals.

-

Commonly used in agriculture, construction, and manufacturing industries.

Circular Bags

Construction: Circular bags are made from a single tubular piece of fabric that forms the sides, with only the top and bottom sewn on.

Advantages:

-

Cost-Effective: The manufacturing process is simpler, which can reduce costs.

-

Flexibility: These bags are highly flexible, accommodating various types of materials.

Applications:

-

Ideal for materials that do not require a rigid container, such as plastic pellets, powders, and certain food products.

-

Frequently used in industries like plastics, pharmaceuticals, and food processing.

4-Panel Bags

Construction: 4-panel bags are constructed from four individual pieces of fabric sewn together to create a square structure.

Advantages:

-

Superior Shape Retention: 4-panel bags hold their shape better than other types, making them excellent for stacking and storage.

-

Enhanced Stability: The rigid structure provides excellent stability, reducing the risk of tipping over.

Applications:

-

Used for materials that require a stable container, such as fine powders, pharmaceuticals, and high-value commodities.

-

Commonly found in the chemical, pharmaceutical, and food industries.

Construction Type and Application

The type of construction chosen for an FIBC can significantly impact its suitability for different products and applications.

Shape and Hold

-

4-Panel Bags: Best for maintaining a square shape, ideal for stacking and efficient storage.

-

U-Panel Bags: Good shape retention with a slightly more flexible structure.

-

Circular Bags: Least rigid but offer flexibility for various materials.

Strength and Safe Working Load (SWL)

-

U-Panel Bags: Often have the best ratings for safe working loads due to their robust design.

-

4-Panel Bags: Also have high SWL ratings, especially suitable for heavy-duty applications.

-

Circular Bags: While flexible, these can also have high SWL ratings depending on the fabric and construction quality.

Specialty Bulk Bags

In addition to standard constructions, specialty bulk bags are tailored for specific needs, ensuring compliance with various industry requirements:

-

Food Grade Bulk Bags: Manufactured in certified facilities, meeting stringent safety and hygiene standards.

-

UN Certified Bulk Bags: Designed for transporting hazardous materials, complying with rigorous safety regulations.

-

Conductive and Antistatic Bags: For handling flammable or explosive materials safely.

Conclusion

Choosing the right type of FIBC construction is crucial for optimizing your material handling operations. Whether you need durability, cost-effectiveness, or superior shape retention, understanding the different types of bulk bag constructions will help you make an informed decision. At Six Star Bulk Bag, we are committed to providing high-quality, safe, and efficient bulk bag solutions tailored to your specific needs. Contact us today to learn more about how we can help you with your bulk bag requirements.

-

FIBC bulk bags have proven to be effective for storing and transporting a variety of products and materials and have also gained a reputation for being a versatile bulk packaging option. One customizable feature of flexible intermediate bulk containers is the bag's top/filling option. With multiple top/filling options, bags can be customized to fit your specific application and operation.

Let's examine four of the most common types of filling options used and hopefully help you determine which option is right for your unique application.

Tie-Down Flap Top Bulk Bags

Tie-Down Flap Top FIBCs are ideal for quick-filling applications. The flap top on this type of bag allows for rapid filling, making each bag easy and quick to fill. The flap closes and can be tied down to ensure the load is securely transported and stored.

Pros:

-

Ideal for quick-filling applications.

-

Allows for rapid fill.

Duffle Top Bulk Bags

Duffle Top FIBCs are another popular bag for quick-filling applications. The bag opens and extrudes outwards to allow rapid filling. The duffle top can be closed and tied to ensure the load is securely transported and stored.

Pros:

-

Ideal for quick-filling applications.

-

Allows for rapid fill.

-

Widely available.

Spout Top Bulk Bags

Spout Top FIBCs are one of the most commonly used types of bags. Spout-top bags are the standard for most filling equipment and are great for controlled filling. The spout top can be closed and tied to ensure the load is securely transported and stored.

Pros:

-

Standard for most filling equipment.

-

Great for controlled filling.

Open Top Bulk Bags

Open Top FIBCs are ideal for quick-filling applications. Open Top bags are usually accompanied by a flat or spout bottom. Open-top bags are commonly used for building materials, scrap products, and lawn and garden applications.

Pros:

-

Ideal for quick-filling applications.

-

Commonly accompanied with a flat bottom or spout bottom.

Duffle Top vs. Spout Top vs. Open Bag

When selecting an FIBC bag for your product, deciding on the top/filling option is crucial. The main choices include open bags, duffle-top bags, and spout-top bags.

-

Open Bag Bulk Bag: This type features a simple hole at the top and is not recommended for most situations due to limited compatibility with filling equipment and minimal protection against dust and spillage.

-

Duffle Top Bulk Bag: These bags feature a thin, lightweight panel on top, providing a larger opening for more flexible filling and emptying options. They can be closed after filling to protect the contents and prevent spillage during transport.

-

Spout Top Bulk Bag: These bags have a spout sewn to the top panel, designed for use with specific filling and discharging equipment. The smaller opening reduces dust and spillage during filling and discharging. The spout can be tied off to secure the contents during transport and storage.

Choosing the Right Bag

-

Duffle Top Bags: Best for operations with multiple machines and need flexibility in filling and discharging.

-

Spout Top Bags: Ideal for setups with one or two machines designed for spout tops, offering better dust and spill protection.

Conclusion

hoosing the right type of bag top/filling option is essential to optimizing your material handling process. Whether you need the versatility of a duffle top, the controlled filling of a spout top, or the simplicity of an open top, Six Star Bulk Bag has the right solution for your needs. Contact us today to learn more about how we can help you with your bulk bag requirements.

-

When choosing flexible intermediate bulk containers (FIBCs), it's essential to consider how you will discharge the bag's contents. Different discharge methods are suited to different applications.

Flat Bottom Bulk Bags

Flat bottom FIBCs are constructed like other bags but lack a discharge option on the bottom. They typically have an open or duffle top and are usually uncoated. These bags are ideal for specific applications, particularly when the user plans to discharge the contents by cutting an X in the bottom. However, finding flat bottom bags in stock can be challenging, and they often require long lead times for orders.

Spout Bottom Bulk Bags

Spout-bottom FIBCs are the most commonly used discharge option. They feature a funnel-like spout at the bottom, secured with a safety tie to prevent leaks. Spout bottoms can be enhanced with safety valves, covers, or flaps to provide additional protection against product leakage. This design is versatile and widely used for various materials.

Conclusion

-

Flat Bottom Bags: Best for specific applications where cutting the bottom is required. Harder to find in stock and requires long lead times.

-

Spout Bottom Bags: Versatile and widely used, offering secure and controlled discharge with additional protection options.

-

FIBC Bulk bags come in various sizes, shapes, and materials, offering a wide range of customizations to suit different applications. One of the critical features to consider when choosing the right bulk bag is the type of closure used to seal the bottom of the bag, as it can significantly affect the integrity and functionality of the bag. There are several types of bottom closures that can be customized to fit your specific needs.

Spout Bottom

A bulk bag with a spout bottom features a funnel-like opening at the bottom, allowing for easy emptying of the bag. The spout is tucked into the bottom of the bag and remains closed until it is ready to be opened for discharge. Spout bottoms are commonly used for storing and dispensing powders and other granular materials. They are the most widely used type of bulk bag bottom closure and can be tailored to various sizes to suit your application.

Benefits:

-

Allows easy emptying with a funnel-like opening.

Spout Bottom with Safety Valve (Iris Closure)

A spout bottom with a safety valve is designed to control the flow of material from the bulk bag. This type of closure is essential for managing the discharge of bulk materials, especially hazardous ones, as it allows the bag to be emptied without releasing dust and particles. The safety valve offers an additional layer of control and safety during the discharge process.

Benefits:

-

Controls the discharge flow, reducing dust and particle release.

Spout Bottom with Cover (Star Closure & Petal Cover)

This closure type incorporates a piece of fabric sewn between the spout and the petal closure, which helps hold the spout in place. A square piece of fabric is then sewn over the spout bottom to secure it. The spout bottom with cover is designed to keep the contents inside the bag contained, minimizing contamination risks and preventing leakage.

Benefits:

-

Minimizes contamination risks and prevents leakage.

Discharge Spout with Flap

The discharge spout with flap, also known as a sanitary flap, features a flap that protects the entire bottom of the bulk bag. This design is often used to facilitate easy discharge, reduce wear on the bottom of the bag, and maintain cleanliness in the discharge area.

Benefits:

-

Protects the bottom of the bag, ensuring cleanliness.

B-Lock Closure

A B-lock closure, also known as a cord lock, uses a cord to secure the spout on the bottom of the bag. This type of closure is effective in preventing accidental loss of contents. B-lock closures come in various lengths and sizes and can be used to replace hand-tied knots. They are also applicable for securing the spout top of the bag.

Conical Bottom

Conical bottom bulk bags are used for materials that do not flow freely, such as dense or sticky substances like clay and slurries. The cone-shaped bottom facilitates the flow of these materials out of the bag, ensuring efficient discharge.

Benefits:

-

Ideal for materials that do not flow freely.

Full Open Discharge

Full open discharge is a type of closure that opens the entire bottom of the bag, allowing all the contents to be released at once. This design is suitable for non-flowable products or those that tend to clump over time. However, it is not recommended for applications where discharge accuracy is critical.

Benefits:

-

Opens the entire bottom for quick and complete discharge.

Full Bottom Discharge

Bulk Bags Full bottom discharge bulk bags, often referred to as “diaper bottom” or “diaper discharge,” feature bottom openings that span the full length and width of the bag. For instance, a 35x35x45 bag with a full discharge bottom will have a discharge opening of 35x35. This type of design allows for extremely fast discharge, making it ideal for applications where rapid emptying is essential.

Benefits:

-

Extremely fast discharge rate.

-

Ideal for applications requiring quick and complete emptying of contents.

Remote Discharge Spout

The remote discharge spout for bulk bags introduces a significant improvement in safety and efficiency. This innovative design allows operators to initiate the bag's emptying process without direct interaction with the bottom of the bag. A side-mounted release rope enables safe discharge from a distance.

Key Benefits:

-

Enhanced Operator Safety: Reduces the risk of injury by eliminating the need to manually reach under the bag.

-

Operational Efficiency: Streamlines material handling, reducing downtime and ensuring a complete discharge with minimal waste.

-

Promotion of Material Flow: Optimized design prevents blockages and ensures a consistent discharge rate.

The remote discharge system is complemented by the use of B-lock closures, which act as secure cord locks, ensuring the discharge spout remains closed until intentionally released, thus preventing accidental spills.

Conclusion

Choosing the right type of bottom closure for your FIBC bulk bag is essential to ensure efficient and safe material handling. Each closure type offers unique benefits tailored to specific applications, from controlling hazardous materials to facilitating the discharge of sticky substances. At Six Star Bulk Bag, we provide a variety of customizable bottom closures to meet your specific needs. Contact us today to find the perfect bulk bag solution for your business.

-

FIBC bulk bags have proven to be highly effective for storing and transporting various products, gaining a reputation as a versatile bulk packaging solution. One customizable feature that enhances their versatility is the top loop construction. With multiple loop options available, these bags can be tailored to fit specific applications and operations.

Let's explore the pros and cons of four common types of lift loops to help you determine which is best for your needs.

Loop Over Loop (Corner Seam Loops)

Loop over loop lift loops, also known as corner seam loops, are the most common type of lift loop construction. In this design, each corner of the bag has a loop sewn into the seam. This allows a forklift to lift the bag, but it requires all four loops to be used simultaneously, making loading and transporting somewhat tedious.

-

Pros: Most common and cost-effective option.

-

Cons: Can be harder to use with forklifts due to the need for simultaneous lifting of all four loops.

Cross Corner Loops

Similar to loop over loop, cross-corner loop bags have loops in each corner, but these loops are sewn into eight points in opposite corners of the bag. This design often requires the bag to be made from circular fabric.

-

Pros: Loops stand upright when the bag is full, making it easier for forklift operators to grab and lift, reducing handling times.

-

Cons: Usually more expensive than loop over loop construction.

Stevedore Straps (Lift Loops)

Stevedore straps are special supporting loops designed for safe handling. Unlike standard four-point lifting, stevedore loops allow lifting from only one or two points. There are three main types:

-

One Stevedore Loop: A single loop pulled through the four standard corner loops.

-

Double Stevedore Loops: Two loops that connect each parallel corner loop.

-

Supporting Stevedore Loops: Additional loops attached to each corner loop.

-

Pros: Multiple lifting options, enabling lifting by one or two loops.

-

Cons: Specialty item, can be more expensive.

Sleeve Loops (Lift Tunnel Loops)

Sleeve or lift tunnel loops are made from the bag's body fabric. These loops are particularly practical for operations using forklifts exclusively.

-

Pros: Simplifies forklift operation, making it the easiest option for forklift operators.

-

Cons: Suitable only for forklifts, limiting its use in other handling methods.

Choosing the right type of lift loop for your FIBC can significantly impact the efficiency and safety of your operations. Each type has unique advantages and potential drawbacks, making it essential to consider your specific application and operational needs when making a selection.

-

Industry-specific vocabulary can often be a source of confusion, and the bulk bag industry is no exception. At Six Star Bulk Bag, we frequently receive questions about terminology. For instance, bulk bags are also known as FIBCs (Flexible Intermediate Bulk Containers), jumbo bags, big bags, and super sacks. This variety in terminology can cause confusion, especially when it comes to terms like stevedore straps. So, what exactly are stevedore straps?

Stevedore Straps Explained

Stevedore straps are additional straps that attach to the standard polypropylene straps sewn into an FIBC. These straps can be purchased separately or with the bulk bags. They loop through the existing lifting loops to provide additional lifting options, making them particularly useful for forklifts. These straps create easy access points for forklifts to move the bags within a facility, which is why they are commonly used in warehouses where FIBCs are handled frequently. Stevedore straps are also known as ‘loading belts’.

Types of Stevedore Straps

There are three main types of stevedore straps commonly used:

Standard (Supporting) Stevedore Straps: They involve four individual straps that attach to each of the straps sewn into the bag. They are useful when the standard straps are not long enough or when extra clearance from the top is needed.

Double Stevedore Straps (Double Loading Belt): This setup uses two longer straps, each looped through two of the straps sewn into the bag. It is ideal for use with forklifts or cranes, as it simplifies the process of inserting the forklift's arms or the crane's hook for lifting.

Single Stevedore Strap (Single Loading Belt): A single strap loops through all four of the bag's sewn-in straps, offering a simple and easy lifting option. This setup is common in facilities using forklifts, as it facilitates easy movement of the FIBC.

Benefits of Stevedore Straps

Using stevedore straps with FIBC bulk bags enhances efficiency and ensures safety. These straps provide a secure and reliable way to move, store, and transport large bulk bags. They help maintain the stability and security of the bags during transport and storage, reducing the risk of accidents, injuries, and damage. It is crucial to install the straps correctly to prevent them from becoming loose or failing during transport. Regular inspection is also necessary to ensure they are in good condition and not worn or damaged.

Should You Use Stevedore Straps with Your FIBCs?

The decision to use stevedore straps depends on your product, application, and facility operations. If your facility frequently uses forklifts, these straps can make handling bulk bags more efficient. However, it's important to note that FIBCs with stevedore straps generally cost more than those without. Despite the higher cost, the efficiency gains in facilities with high forklift use often make stevedore straps a worthwhile investment.

Bulk bags, or FIBCs (Flexible Intermediate Bulk Containers), are highly versatile containers used for storing and transporting various products. However, a common question is, "Are FIBCs watertight or waterproof?" Here, we address this query and offer potential solutions.

Are Bulk Bags Watertight or Waterproof?

FIBCs are not inherently watertight or waterproof. Made from woven polypropylene, the fabric is not designed to fully prevent water ingress or egress. Some bags have a polypropylene laminate coating on the inside, outside, or both, which acts as a moisture barrier. While this reduces fine material leakage, it does not make the bags completely waterproof.

Can You Make Bulk Bags Watertight?

Several types of closures can enhance a bulk bag's water resistance. The most common is the drawstring top, which uses a rope or string to tighten the bag, keeping liquids out but being somewhat difficult to manage. Other options include flap tops, which cover the opening with fabric secured by snaps or buttons, and valve tops, which use a rubber or plastic valve.

For bottom closures, the spout is standard, allowing for controlled discharge. Other options include gusseted bottoms, which help the bag stay upright, and tie closures using cloth or string.

Can You Make Bulk Bags Waterproof?

Though not completely waterproof, several methods can improve moisture protection for FIBCs. Using polyethylene liners, which are thin plastic inserts fitting inside the bulk bag, adds a layer of protection. These can be separate liners or custom pre-lined bulk bags. Form-fit liners, designed to fit snugly inside, are ideal for transporting liquids but still do not make the bag entirely waterproof.

Understanding these options allows you to better protect your products during storage and transportation.

At Six Star Bulk Bag, we frequently receive questions about the construction of Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, and how to choose the right type. Our goal is to ensure our customers select the best bag for their specific product and application. The decision often hinges on whether the bag is coated or uncoated. Let’s explore the differences between these two types and their common uses.

What is an Uncoated FIBC?

Uncoated FIBCs are made by weaving together strands of polypropylene. Due to this woven construction, fine materials may seep through the weave or sew lines. For instance, if you pack a powder in an uncoated bag and hit the side, you might see a cloud of product escape. While this is acceptable for some applications, it is not for others. Additionally, the weave allows air and moisture to pass more easily through the bag, which can impact the stored product.

Common uses for uncoated bags:

-

Transporting/storing specific types of food grade and non-food grade products.

-

Transporting/sorting granular products the size of rice grains or larger, such as beans, grain, popcorn, and seed.

-

Transporting products that need to breathe.

What is a Coated FIBC?

Coated FIBCs are similar to uncoated bags but with an added layer of polypropylene film that seals the small gaps in the weave. This film can be applied to either the inside or outside of the bag, with the inside being more common to prevent powders from getting stuck in the weave during discharge. To determine if a bag is coated, press the weave together; if it does not spread apart, the bag is likely coated.

Benefits of coated bags:

-

Provides additional protection from contaminants like dust, moisture, and dirt.

-

Acts as a moisture barrier, preventing fine powders from escaping when the bag is hit.

-

Useful for packing small granular or powdered products.

Common uses for coated bags:

-

When a moisture barrier is needed.

-

Transporting dry flowable products in powder, crystal, granule, or flake form, such as cement, detergents, flour, salt, fine minerals, sand, and sugar.

-

Sometimes used with a poly liner for extra protection.

When Coated Bulk Bags Are Not Enough

Coating acts as a moisture barrier but does not make the bag waterproof. For extremely fine granular products and powders, additional features like sift-proof seams may be required to prevent the product from escaping through sew holes. While this adds to the cost, it ensures better containment. In cases where even more protection is needed, bags with polyethylene liners are recommended, such as for powdered sugar.

Conclusion

Choosing between coated and uncoated FIBCs depends on the specific requirements of your product and application. Coated bags offer additional protection and are suitable for finer materials that need moisture barriers. Uncoated bags, on the other hand, are ideal for products that require breathability. At Six Star Bulk Bag, we provide a variety of FIBC options to meet your needs. Contact us today to find the perfect bulk bag solution for your business.

-

When researching Flexible Intermediate Bulk Containers (FIBCs) beyond Six Star Bulk Bag, you might come across varying information about UV stabilization. This feature often leads to confusion due to the abundance of misinformation. Here, we clarify what UV stabilization means, how it impacts bulk bags, and the safety of storing these bags outside.

FIBCs and UV Degradation

You may have heard claims that FIBCs are “UV safe” or “UV resistant.” While partially true, it doesn't imply complete immunity to UV degradation. Bulk bags can resist UV rays to some extent, but prolonged sun exposure will eventually lead to their degradation. All FIBCs have an hour rating that indicates their UV exposure limit. At Six Star Bulk Bag, we strongly advise against storing bags outside due to the risks associated with prolonged sun exposure.

UV degradation happens when bags are exposed to UV rays over extended periods. All synthetic polymers, including the polypropylene used in FIBCs, deteriorate under UV exposure. UV rays break down the chemical bonds in polypropylene, creating free radicals that weaken the material. This degradation can cause the bags to crack, become unstable, and ultimately fail, posing significant risks of injury or death.

Polymer Stabilizers

If outdoor storage isn't recommended, why are FIBCs sometimes labeled as “UV safe”? This confusion arises because FIBCs are manufactured with polymer stabilizers. These stabilizers are chemical additives mixed with polypropylene during production to prevent material degradation. They absorb UV rays and dissipate them as low-level heat, enhancing the bags' UV resistance. However, these stabilizers break down over time, so knowing your bag’s UV exposure rating, usually measured in hours, is crucial.

Why This Matters

Safety is paramount at Six Star Bulk Bag. We prioritize helping customers find the right bag for their needs, offering safe handling tips, and guiding them through complex requirements, such as food-grade standards. Without polymer stabilizers, UV exposure would significantly degrade the bags, making them unsafe. Even with these stabilizers, there are limits to how long a bag can safely be exposed to UV rays.

Our FIBCs comply with the ISO 21898 Standard, recommending that bag exposure to UV rays should not exceed 200 hours. This limit can vary based on location; for instance, the sun’s intensity in Arizona differs significantly from the often cloudy conditions in Washington state, affecting how quickly a bag degrades. Given these variables, we never recommend outdoor storage. If unavoidable, consult your supplier for specific guidance regarding your use case.

Conclusion

Understanding UV stabilization is crucial for the safe use of FIBCs. While polymer stabilizers provide some protection against UV rays, they are not foolproof, and prolonged exposure can still lead to degradation. Always consider your environment and consult with suppliers to ensure your FIBCs are used safely and effectively. At Six Star Bulk Bag, we are committed to providing reliable, safe bulk bag solutions tailored to your needs.

The biomass industry faces numerous challenges, particularly in adhering to stringent regulations. Ensuring proper documentation during the transportation and storage of materials is crucial. One effective way to manage this is through the use of document pouches. Let's explore what they are, why they are important, and how they can assist in transporting biomass and hazardous products.

Document Pouches for Bulk Bags

Document pouches are small plastic pouches sewn into the side of FIBCs (Flexible Intermediate Bulk Containers). They are designed to hold important documents related to the bag's contents, such as legal information and details about hazardous materials. Multiple document pouches can be attached to a single bag, making them versatile and flexible for various needs.

Why Document Pouches Are Important

Consider a scenario where a company needs to transport biomass across different regions. Without proper labeling and documentation attached to the bags, they risk legal complications if inspected by authorities. Document pouches ensure that all necessary documents are securely attached to the container, reducing the risk of losing paperwork or forgetting to include it during transport.

How Document Pouches Could Help

By using document pouches, companies can ensure compliance with legal requirements and avoid costly and time-consuming legal issues. These pouches provide a secure way to attach essential documentation to bulk bags, ensuring that all necessary information is readily available and reducing the risk of legal complications.

Conclusion

The use of document pouches in the biomass industry is a simple yet effective measure to ensure compliance with legal requirements and avoid legal issues. At Six Star Bulk Bag, we understand the importance of these tools and are committed to providing solutions that help protect your business.

Introduction to Flame-Retardant Bulk Bags

Flame-retardant bulk bags are an innovative solution in the FIBC industry, designed to withstand high temperatures and resist flames while complying with various regulations. One significant aspect of these bags is halogenation, a process that enhances their flame-retardant properties.

Chemical Additives in FIBCs

FIBCs are made from woven polypropylene, which allows for the incorporation of various chemical additives during manufacturing. These additives can impart specific properties to the bags, such as UV resistance or insect repellence. Recently, flame-retardant additives have become increasingly important, particularly for applications requiring enhanced fire safety.

Understanding Halogenation

Halogenation involves adding halogens—elements like fluorine, chlorine, bromine, iodine, and astatine—to a material. In the context of FIBCs, halogens are added to the polypropylene resin during manufacturing, resulting in halogenated flame-retardant bulk bags. These bags are more effective in preventing fire spread by interfering with the fire's physical chemistry, thereby limiting its development.

Flame-Retardant Bulk Bags: Halogenated vs. Non-Halogenated

Flame-retardant FIBCs are available in halogenated and non-halogenated forms. Halogenated bags are particularly effective in scenarios where enhanced fire prevention is critical. However, they do have a downside: when they burn, they can release toxic substances. Non-halogenated bags, on the other hand, provide flame resistance without the risk of toxic emissions.

Conclusion

Halogenation significantly enhances the fire-resistant properties of FIBCs, making them suitable for applications where fire safety is paramount. Both halogenated and non-halogenated flame-retardant bulk bags offer unique benefits, catering to different needs and ensuring the safe transport and storage of materials.

Flame-Retardant FIBCs are designed to address specific safety concerns, providing protection for materials, property, and employees, and ensuring compliance with legal regulations. These bags are a notable innovation within the FIBC industry, offering enhanced safety features for various applications.

Flame Retardant FIBC Bulk Bags

Flame-retardant FIBCs are engineered to resist burning and prevent the spread of fire in certain conditions. Here are some key features and benefits of these advanced bulk bags:

High Melting Points: These bags can have a high melting point of up to 168.39 degrees Celsius, allowing them to be used in applications where standard bags might fail or catch fire.

Flexible Heating Range: Depending on the manufacturer, flame-retardant bags can withstand temperatures ranging from 35 degrees Celsius to 350 degrees Celsius. This broad range makes them suitable for various environments and applications.

IS Certification: Six Star Bulk Bag offers flame-retardant bags that meet IS:15601 flammability standards. This certification ensures that our bags adhere to strict regulations and meet demanding application requirements.

Heat and Flame Resistance: Unlike standard FIBCs, which undergo molecular changes and expand when exposed to heat, flame-retardant bags can withstand much higher temperatures without significant changes.

Halogenation Options: Available in both halogenated and non-halogenated versions, these bags use halogens as active flame retardants to prevent the spread of fire. For more information on halogenation, refer to our article on "What is Halogenation? What does it have to do with Bulk Bags?"

These features make flame-retardant bags an ideal solution for a variety of applications, providing enhanced safety and compliance with industry standards.

Conclusion

Flame-retardant FIBCs represent a significant advancement in bulk bag technology, offering critical safety benefits for various industries. At Six Star Bulk Bag, we are committed to providing innovative and reliable solutions to meet your specific needs.

Ensuring Safety with FIBCs

Workplace safety is a top priority at Six Star Bulk Bag. We strive to provide our customers with the safest, most reliable bulk bags tailored to their specific needs. One critical aspect of safety is managing static electricity in facilities using FIBCs. Static buildup can lead to dangerous electrical discharges, posing significant risks, especially when handling hazardous or volatile materials. This is where Type D bulk bags come into play.

Understanding Type D FIBC Bulk Bags

There are four main types of bulk bags: A, B, C, and D. Type D bulk bags are specifically designed to prevent static buildup and discharge. Unlike standard Type A bags, Type D bags are made from anti-static materials that actively dispel static charges without needing grounding.

Comparing Different Types of FIBCs

-

Type B: These bags have low breakdown voltage to prevent brush discharge but lack active static dissipation mechanisms.

-

Type C: These bags require grounding through a wire to safely dissipate static charges.

-

Type D: Made from anti-static materials like CROHMIQ™, Type D bags do not need grounding. They actively resist and dispel static buildup, offering enhanced safety.

What is CROHMIQ™?

CROHMIQ™ is a fabric used in Type D bulk bags that resists static electricity buildup. It is renowned as a leading material for non-grounded static-resistant bulk bags, providing a high level of safety in environments where static discharge poses significant risks.

When to Use Type D FIBCs

If you handle volatile or combustible materials, using Type C or D bags is crucial. Type D bags are recommended for their convenience and safety, eliminating the need for grounding and reducing the risk of human error. This makes them ideal for transporting materials where static discharge could have catastrophic consequences.

Conclusion

At Six Star Bulk Bag, we prioritize safety and recommend using Type D bags for handling hazardous materials. Please note that Six Star Bulk Bag does not produce Type D bulk bags but can provide guidance on the best practices for using and selecting the appropriate FIBCs for your needs.

-

At Six Star Bulk Bag, we often delve into various aspects of FIBC construction. With numerous variations and combinations, it's our goal to cover as many types as possible, no matter how specialized. What exactly are bulk bag flaps? What purpose do they serve? And would they be beneficial for your application?

What is a Bulk Bag Flap?

A bulk bag flap is a fabric piece that covers the top or bottom of a FIBC, matching the bag's dimensions. Made from the same woven polypropylene material as the bag, the flap attaches to one of the four sides, creating a cover that can be opened and closed. It is designed to protect various bag openings or closures (such as spout top/bottom, open top, or full bottom discharge), offering additional security for the contents.

Industry Uses and Applications for FIBC Flaps

Bulk bag flaps are invaluable in several industry applications:

-

Contamination Prevention: In scenarios where contamination is unacceptable, a flap can cover the opening or discharge port, preventing external contaminants from entering the bag.

-

Protection During Transport and Storage: If there's a risk that the bottom discharge port might get damaged during transport or storage, a flap provides an extra layer of protection, safeguarding the port from potential damage.

-

Shipping Container Transport: When transporting products via shipping containers, a flap can protect the bag's bottom and/or top during transit.

-

Covering Bottom Spouts: Commonly, flaps are used with bottom spouts. Once a spout bottom is tied shut, the flap covers and protects the spout apparatus.

Important Note

Adding a flap generally increases the cost of a bag. Standard bags do not include flaps to maintain cost efficiency. If you require a flap, inform your supplier, as it will affect the price per bag.

Conclusion

Bulk bag flaps provide critical protection and contamination prevention in various applications. At Six Star Bulk Bag, we aim to offer comprehensive solutions tailored to your specific needs.

-

The FIBC industry is always adapting to meet the changing needs of its users. One recent innovation making a significant impact is the over-sized spout bottom FIBC, designed to address specific operational challenges. These bags feature a spout that is 28 inches in diameter, double the standard 14-inch size, initially developed for the hemp industry but beneficial across various sectors.

Addressing the Challenge of Bridging

Bridging occurs when materials inside the bag clump together during discharge, clogging the spout. This issue is common with high moisture content products like organic materials and certain powders, which can disrupt operations and slow production. Traditionally, users might cut the bag to bypass the spout, leading to safety hazards and wasting the bag.

Over-sized spout bottom FIBCs tackle bridging effectively. The larger spout and faster discharge rate prevent material buildup, enhancing both reliability and safety.

Boosting Efficiency

These bags enable faster discharge rates while maintaining control over material release, similar to standard spout bags. This increased efficiency reduces the time and effort needed for transferring materials, benefiting production or repackaging processes. Combined with reduced bridging, these bags can significantly improve operational workflows.

Broad Industry Applications

Over-sized spout bottom FIBCs are ideal for various industries, particularly those dealing with high moisture products or powders that tend to clump. Their design helps prevent bridging, making them a great choice for:

Fresh organic materials like hemp and agricultural goods

High moisture powders that tend to stick together during transportation and storage

Exploring the benefits of over-sized spout bottom FIBCs can improve efficiency and safety in operations handling these materials. At Six Star Bulk Bag, we are enthusiastic about these innovations and their potential to address common industry challenges effectively.

Reducing material use and waste is crucial for creating an environmentally friendly business. Less waste results in fewer items going to landfills, and implementing recycling and reuse strategies offers several benefits:

-

Decreasing Costs: Reusing materials means spending less on essential containers and packing bags, allowing your company to get more value from investments. Additionally, many companies offer discounts for reused or recycled materials, making them cost-effective.

-

Preserving Limited Resources: Plastic products often require finite resources like petroleum or oil. By recycling or reusing polypropylene bags, your company can reduce its reliance on these materials and conserve them for other operations.

-

Reducing Energy Use: Producing new products requires significant energy, and recycling processes can also be energy-intensive. Reusing materials saves energy by lowering production levels, and ordering fewer new products reduces the energy used by shipping companies.

-

Increasing Product Lifespan: Reusing products maximizes the value of investments, as items are used until they can no longer perform their functions. Recycling extends the lifecycle of materials by keeping them in production longer, preventing them from entering landfills prematurely.

While recycling is crucial, incinerating plastic materials to create new products can release carbon emissions and greenhouse gases. Reducing and reusing materials can decrease the number of items sent to recycling plants, improving your environmental impact.

How to Reduce Waste in Business

Manufacturing waste can increase costs and harm the environment. Implementing greener habits focused on waste reduction can make a significant difference. Here are some strategies:

-

Choose Bulk Packaging: Bulk bags are excellent for shipping or storing large amounts of products, allowing you to use fewer packaging materials while maintaining product quantity.

-

Reuse and Recycle Packaging: Decrease landfill waste by reusing and recycling materials like polypropylene bags. Cleaning and inspecting reusable products can significantly reduce waste with minimal effort. Damaged or unusable materials can go to recycling facilities to minimize plastic waste.

-

Opt for Used or Refurbished Packing Materials: Support waste reduction by purchasing used packing materials. Used or refurbished bulk bags often have excellent functionality and undergo comprehensive quality control.

-

Buy Materials in Bulk: Purchasing in bulk reduces the packaging materials used for your order, resulting in less waste. Consolidating orders with the same supplier can further limit the materials discarded later.

-

Select Space-Efficient Bulk Containers: Refurbished FIBCs can optimize storage space effectively. Their stackable design allows for efficient use of storage areas, reducing material needs.

How to Store and Ship Products With Bulk Bags

Used and reusable bulk bags are cost-effective storage and shipping solutions for many industries, offering numerous benefits:

-

Stackable: Bulk bags are sturdy and fit well together, allowing for optimized use of vertical space in warehouses and shipping containers. They can be folded and stacked when not in use, saving space compared to other materials.

-

Lightweight: FIBCs are lightweight, making them excellent for shipping as they reduce transportation costs. They are easy to store and manage due to their light weight.

-

Reusable: Bulk bags can be reused for multiple applications. They can be cleaned to meet residue standards and checked for damages between uses, offering long life spans and cost savings. When no longer usable, they can be recycled.

-

Versatile: Available in various shapes and configurations, bulk bags are suitable for multiple industries and products. Their strength supports heavy materials in construction, while their shapes help agricultural companies store and ship compact items. Some bags come with lids for better protection and sealing of chemicals.

At Six Star Bulk Bag, we offer a Multi-Use Bulk Bag Program that focuses on reusability and sustainability. This program ensures that our bulk bags are inspected, refurbished, and reused, significantly reducing waste and environmental impact. By joining our Multi-Use Bulk Bag Program, businesses can achieve greater operational efficiency and support environmental conservation efforts. For more details, check out our Multi-Use Bulk Bag Program.

-

Reducing shipping and storage costs is always beneficial for your business, allowing you to allocate savings to other crucial areas. Here are ten practical tips to help you save on shipping costs for both small and large businesses:

-

Use Bulk Bags Flexible intermediate bulk containers (FIBCs) or bulk bags are a cost-effective and durable solution for storing and transporting various materials, such as grains, agricultural products, fertilizers, pharmaceuticals, and building materials. Bulk bags offer several advantages:

-

Storage Capacity: Available in various sizes and styles, they can store between 1,000 and 5,000 pounds.

-

Weight: Bulk bags are lightweight, reducing shipping costs compared to heavier containers.

-

Durability: These bags withstand heavy-duty environments without needing additional packaging materials or pallets.

-

Stackability: Bulk bags can be stacked to maximize warehouse space and collapse for compact storage when not in use.

-

-

Lower the Package’s Dimensional Weight Carriers charge based on the greater of the package’s dimensional or actual weight. By packing more efficiently and choosing the right-sized box, you can reduce the dimensional weight and lower shipping costs.

-

Avoid Expedited Shipping Costs Instead of paying for expedited shipping, consider establishing a warehouse or fulfillment center in a central location to reach customers quickly. Efficient packaging processes can also help avoid the need for expedited shipping.

-

Consolidate Your Shipments Shipping products in bulk rather than as needed reduces packaging and costs. Bulk shipments ensure time-sensitive orders are shipped faster and more efficiently.

-

Invest in Third-Party Tracking and Insurance Services Third-party tracking services hold carriers accountable for delivery dates, while shipping insurance reimburses you for lost or damaged packages. These services can be more cost-effective through third parties.

-

Negotiate With Carriers Businesses that ship in bulk can negotiate discounts with carriers. Even without large volumes, you can seek loyalty discounts. E-commerce businesses can ask their order fulfillment companies to share savings from bulk shipping.

-

Consider Prepaid Shipping If you frequently ship orders of the same weight and dimensions, prepaid shipping labels can save you money on upfront costs and streamline the packaging process.

-

Implementing modern Software Cloud-based systems can enhance efficiency, customer satisfaction, and reduce costs. These systems manage orders, shipments, returns, and warehousing while accurately tracking inventory levels.

-

Check Out Discounted Shipping Supplies Large shipping companies often offer discounted or free packaging supplies, such as dunnage, bubble wrap, and peanuts. Purchasing these supplies in bulk can lead to significant savings.

-

Consider Hybrid Services Logistics companies offer hybrid services where carriers pick up packages and ship them to the post office closest to their final destination. Although delivery may be slower, this method can save on shipping costs for smaller items.

Save Money Using Recycled Bulk Bags

Purchasing recycled bulk bags is an excellent way to reduce shipping weight and costs. Reusing bulk bags extends their lifespan and saves money on new packaging materials. These lightweight bags offer the same quality and safety as new ones and are more affordable. Buying bulk bags in bulk further reduces costs per bag, providing more value for your money. Additionally, using recycled bulk bags helps reduce packaging waste in landfills, contributing to environmental conservation.

For a more sustainable approach, check out our Multi-Use Bulk Bag Program. This program focuses on reusability and sustainability, offering significant cost savings and promoting environmental responsibility.

-

Transporting sensitive materials, from valuable raw resources to regulated substances, is a routine task for many bulk bag users. Often, these materials are handled by third-party shipping companies. This raises a crucial question: how can you ensure your materials haven’t been tampered with and that they arrive in the same condition they left?

Recent innovations in the bulk bag industry address these security concerns effectively. Let’s explore the benefits of these new products and how they can enhance your operations.

Tamper Evident FIBCs

Tamper Evident bags are a cutting-edge solution designed to reveal tampering and damage through visual inspection. These bags are ideal for organizations that frequently ship sensitive or critical materials and those who have experienced tampering or damage by third-party shippers.

Key features of Tamper Evident bulk bags include:

-

Specialized Patterning: Constructed with specific patterning of woven polypropylene, these bags feature carefully matched patterns across various sections. Any deviations from these patterns may indicate tampering or damage.

-

Continuous Stitching: The continuous stitching pattern on all seams of the bag provides another way to detect tampering. Breaks in this stitching pattern serve as visual evidence of tampering or damage.

-

Security Eyelets: These eyelets around the filling and discharge spouts can be secured with cable ties, preventing unauthorized access.

-

Double-Walled Spouts: Equipped with materials that seal the bag, any tampering or breakage of this seal is easily identifiable by the end-user.

These features enable the identification of tampering or damage during the shipping or storage of sensitive materials, providing optimal security and confidence for vendors, end-users, and shipping companies.

Talk to Your Distributor About Tamper Evident FIBCs

If you frequently ship sensitive materials or are concerned about the security of your shipments, Tamper Evident bulk bags might be the solution. However, the quality of these bags can vary significantly between vendors. It’s essential to choose a vendor that provides high-quality Tamper Evident bags and excellent customer support to ensure the security of your materials and your peace of mind.

If you are searching for a reliable distributor, check out our recent article “5 Things to Look For When Choosing a FIBC Supplier.” For more information on deploying Tamper Evident bags in your operations, Six Star Bulk Bag can help. Contact us today to learn more.

-

For various products and applications, specialty bags like coated FIBCs and FIBCs with pre-installed liners are necessary for safe use. However, determining when to use a lined bag versus a coated bag can be challenging. At Six Star Bulk Bag, we frequently address this question and aim to clarify it in this section.

FIBC Liners

Poly liners are plastic inserts placed inside FIBCs to prevent leaks. They are particularly useful for storing and transporting fine powders or when an extra moisture barrier is required. These liners are especially beneficial in the food and pharmaceutical industries. When combined with a multi-use bag (6:1 safety ratio), the liners can be easily removed, discarded, and replaced, allowing the bulk bag to be reused. This reusability is one of the main advantages of poly liners over bulk bags with pre-installed liners.

Lined Bulk Bags

While companies can purchase and insert poly liners into any FIBC, they can also buy bags with pre-installed liners. These lined bulk bags offer a variety of options, making them suitable for a wide range of products and applications. However, the main disadvantage is that these liners are usually sewn into the seams or tabbed to the bag’s material, making them non-removable. This limits the flexibility for reuse compared to removable poly liners.

Coated Bulk Bags

Coated FIBCs are constructed similarly to standard FIBCs but with an added polypropylene film to the fabric before the bag is sewn together. This film seals the small gaps in the poly weaves and can be applied inside or outside the bag. Inside coating is more common as it prevents powders from sticking in the weave during discharge. Identifying a coated bag can be tricky if you're not familiar with FIBCs. The easiest method is to press the weave together; if it doesn’t spread apart, the bag is likely coated.

The primary benefit of a coated bag is the added protection it offers against contaminants such as dust, moisture, and dirt. This makes coated bags ideal for environments where these factors are a concern.

Common uses for coated bags include:

-

Transporting dry flowable products in powder, crystal, granule, or flake form, such as cement, detergents, flour, salt, fine minerals like carbon black, sand, and sugar.

-

Using a poly liner along with a coated bag for additional protection.

When to Use Liner, Coated, or Lined Bulk Bags

Choosing between a poly liner, lined bag, and coated bag depends on your product and application. Coated bags offer less protection against contamination than lined bags and poly liners but are more economical. For enhanced protection, especially with fine powders, poly liners, and pre-lined bags are the best options due to the potential for fine powders to seep through woven polypropylene.

When deciding between removable poly liners and pre-installed liners, consider whether you will be reusing the bags and if you need a specialty liner (such as aluminum foil, lay-flat, baffle, or form fit). Removable liners typically come in standard polypropylene, so if you need a specialty liner, a pre-lined bag is the best choice. For reusability, removable poly liners are ideal as they can be replaced, allowing the FIBC to be used for different products or applications. Simply remove the used liner, discard it, and insert a new one to prepare the bag for its next use.

-

Flexible Intermediate Bulk Containers (FIBCs) are ideal for transporting and storing large quantities of products safely and efficiently. Widely used across industries such as agriculture, chemicals, pharmaceuticals, pet food, and metals & mining, these bulk bags often need to be paired with poly liners for enhanced functionality and protection.

Bulk bags with poly liners are frequently used for food products and very fine powders. These liners are inserted into each bag and are compatible with both duffle top and spout top bags. They can also come with attachment tabs, allowing the liners to be sewn, tied, or glued to the bag, preventing the liner from discharging.

Below are four common types of bag liners:

-

Lay-Flat Liners

-

Form-Fit Liners

-

Baffle Liners

-

Tubular Liners

-

Aluminum Liners

Let’s explore the features and common uses of these types of bag liners.

Lay-Flat Liners

Lay-flat polyethylene liners are the most common type of liners. They are cylindrical, open at the top, and often heat-sealed at the bottom. If heat-sealed, the liner must be cut to discharge the product. Lay-flat liners can be pre-inserted in the bag or purchased by the roll. Key features include:

-

Oxygen barrier

-

Moisture barrier

-

Chemical resistance

-

Anti-static properties

-

High strength

Form-Fit Liners

Form-fit poly liners are designed to match the exact shape of the bag, including the spout inlet and outlet. They enhance the bag’s performance and protect the product from contamination during processing, storage, and transportation. Form-fit liners allow for consistent filling and discharge as they do not have folds or pleats. Key features include:

-

Oxygen barrier

-

Moisture barrier

-

Chemical resistance

-

Anti-static properties

-

High strength

Baffle Liners

Form-fit baffle liners provide superior package performance and can reduce storage and shipping costs. They maintain a square shape, preventing the product from pushing outward and creating a rounded bag. This square shape helps save space on pallets and in trucks. Key features include:

-

Increased bag stackability

-

Enhanced stability

-

Can hold up to 30% more product in a given space

-

Protection from contamination

-

Formed spouts for filling and discharge

Tubular Liners

Tubular liners, similar to standard gusset liners, are made from polyethylene and are pre-inserted into the bag before leaving the manufacturing facility. Unlike gusset liners that have a sealed bottom, tubular liners have an open bottom that can be fed through the spout, eliminating the need for cutting during discharge. Tubular liners offer several advantages:

-

Application Suitability: Ideal for spout bottom bags, allowing efficient filling and discharging.

-

Cost Savings: Generally more cost-effective than form-fit liners.

Aluminum Foil Liners

Form-shaped aluminum liners, or foil liners, enhance filling, discharging, handling, and stability. They offer excellent protection against moisture, oxygen, and UV light, making them compatible with a wide variety of bags. Foil liners are made from aluminum-laminated films, ensuring product quality and integrity. Key features include:

-

Preventing product damage and contamination

-

Available with top and/or bottom spouts for safe filling and discharge

-

Moisture and oxygen protection

-

Customizable materials for specific applications

Which Liner is Right for My Application?

Choosing the right liner depends on what you’re packing in the bag. For more detailed information on bulk bag poly liners and to explore our offerings, visit the poly liners page on our website.

-

Polyethylene liners, often referred to as poly liners, are flexible plastic liners designed to fit inside flexible intermediate bulk containers (FIBCs or bulk bags). These liners provide an extra protective layer for both the product and the bulk bag, making them highly useful in a variety of industries and applications.

Using Poly Liners with Chemicals

FIBCs are generally resistant to many types of chemicals. However, in some cases, additional protection is necessary. Using poly liners with bulk bags prevents chemicals from seeping through the fabric weave and seams of the FIBC. It also protects the woven polypropylene from chemical contact, which can increase wear and tear on the bag.

Using Polyethylene Liners with Fine Powders

Flexible intermediate bulk containers are made of woven polypropylene, creating a strong, flexible, and lightweight material. However, this weave can pose problems when handling fine materials. Fine powders can leak through the bag during transport, maneuvering, and filling. Poly liners are essential in these cases to prevent fine powders from escaping through the body and seams of the bag. They should be tied at the top after filling to ensure the material is contained.

Using with Sensitive Materials

Polyethylene liners not only protect the FIBC but also provide additional protection for the contents. In industries where contamination is unacceptable, such as food and pharmaceuticals, poly liners prevent moisture, dust, and other contaminants from reaching the materials inside the FIBC.

Common Industry Applications

Polyethylene liners can be used across various industries, depending on the material being stored or transported. Some key industries include:

Food Industry: The food industry frequently deals with fine powders and sensitive materials where contamination is unacceptable. Poly liners paired with food-grade FIBCs ensure maximum safety and prevent contamination.

Pharmaceutical Industry: Similar to the food industry, the pharmaceutical sector requires stringent contamination prevention. Poly liners help protect pharmaceutical materials from contaminants and moisture.

Petrochemical Industry: This industry includes products like fertilizers such as UREA and other powdery chemicals. The use of poly liners in this industry helps maintain the purity and quality of the materials being transported and stored.

Polyethylene liners offer significant advantages for numerous applications, providing essential protection for both the contents and the bulk bags themselves.

The use of FIBC liners has significantly increased as bulk bags become more prevalent in the food, pharmaceutical, and chemical industries. This rise in usage has led to a greater need for information on selecting the appropriate liner for specific products and applications.

Limits of Standard FIBC Liners

For most products and applications, a standard polyethylene liner is more than sufficient. These liners are extremely common in the food and pharmaceutical industries where preventing contaminants from entering the product is crucial. However, polyethylene liners have their limits. They are unable to withstand temperatures exceeding 170°F, and at 195°F, the material begins to soften and melt, potentially contaminating the product. In these high-temperature scenarios, a different type of liner is necessary.

Polypropylene Liners

Polypropylene liners are designed for situations that require higher temperature resistance. These liners are generally thicker and sturdier than standard polyethylene liners, making them suitable for specific applications. Polypropylene liners can withstand product temperatures of up to 295°F, significantly higher than the 200°F limit of standard FIBCs without a liner and the 170°F limit of standard polyethylene liners.

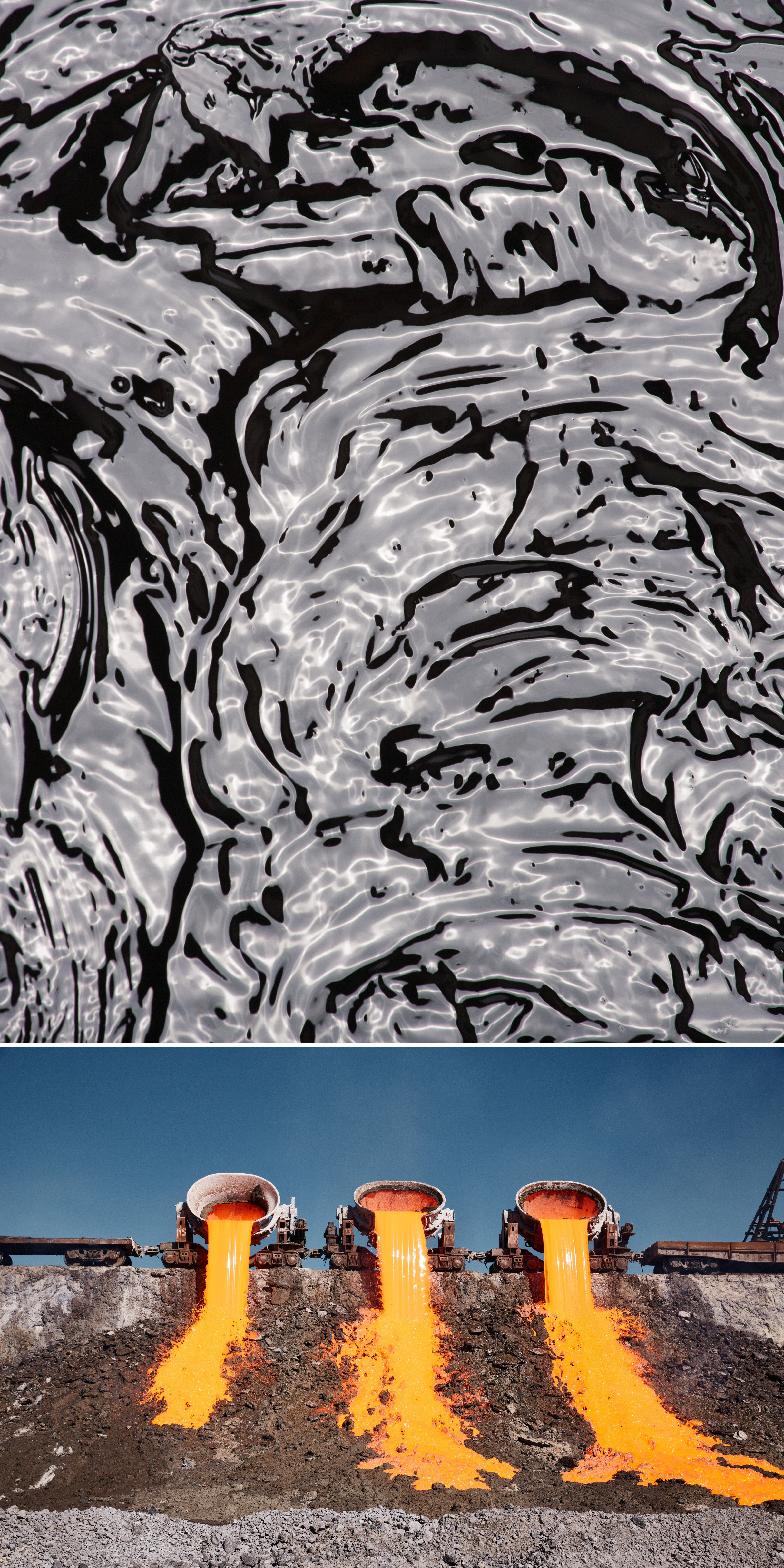

Special Applications for Bitumen

Six Star Bulk Bag specializes in creating bulk bags designed for transporting and storing Bitumen. These bags are constructed to hold liquid and include specialized polypropylene liners capable of withstanding high temperatures, making them ideal for the transport and storage of Bitumen. Our professional approach ensures that the bags are not only robust but also provide maximum safety and efficiency for your operations. Additionally, our bags can maintain their standing shape even when Bitumen is poured in a liquid format, ensuring stability and ease of handling. This ability to hold their shape helps with storage efficiency, maximizing the use of available space and making them easier to stack and store.

Very High-Temperature Products Packaged and Transported in Bulk Bags

Very high-temperature products that are often packaged and transported in bulk bags include:

Bitumen/Asphalt: Used in road construction and roofing materials, bitumen needs to be transported at high temperatures to maintain its liquid state.

Molten Sulfur: Common in the chemical industry, molten sulfur is often transported at temperatures around 120°C (248°F) to keep it in a liquid state.

Hot Resins: Used in various manufacturing processes, resins are often transported at elevated temperatures to keep them in a workable state.

Hot Wax: Utilized in various industrial applications, hot wax needs to be maintained at high temperatures during transport to prevent solidification.

Certain Petrochemicals: Some petrochemical products require high-temperature transport to remain in a liquid state or to ensure proper chemical stability.

Molten Metal Powders: Used in specialized manufacturing processes, these powders may need to be transported at high temperatures to maintain their desired properties.

Hot Liquid Chemicals: Various chemical products that are stable at high temperatures but would solidify or become unusable at lower temperatures.

These products require bulk bags with specialized liners, such as polypropylene liners, which can withstand high temperatures without degrading, ensuring the safe and efficient transport of the materials.

In summary, selecting the appropriate liner for your FIBC is crucial for ensuring the safe and effective use of bulk bags, especially in high-temperature applications. Polypropylene liners are the preferred choice for such scenarios, offering superior heat resistance and durability.

Tubular bulk bag liners are a type of polyethylene liner pre-inserted into flexible intermediate bulk containers (FIBCs) before they leave the manufacturing facility. While they share similarities with standard gusset liners, the key difference lies in the design of their bottom opening. Unlike gusset liners, which have a sealed bottom that needs to be cut during discharge, tubular liners have an open bottom that can be fed through the spout, eliminating the need for cutting during discharge.

Availability and Purchase

Tubular liners are typically pre-inserted into the bulk bags before purchase. In contrast, gusseted liners can either be bought in rolls for manual insertion by the purchaser or pre-inserted into the bags. Form-fit liners are exclusively available pre-inserted into the bags before purchase.

Why Choose a Tubular Liner?

There are several scenarios where a tubular liner may be more beneficial:

Application Suitability: If your operation uses a spout bottom bag and requires a liner, a tubular liner is ideal. It allows the liner to be fed through the bottom spout during manufacturing, enhancing the efficiency of both filling and discharging processes.

Cost Savings: Tubular liners generally cost less than form-fit liners. If your current use involves form-fit liners but could be substituted with tubular liners, you might achieve significant cost savings. Discussing this option with your supplier could lead to a custom bag solution that better fits your needs and budget.

In summary, tubular bulk bag liners offer practical advantages in specific applications, particularly those involving spout bottom bags. Their efficient design and cost-effectiveness make them a viable option for various industries and applications. For more information on how tubular liners could benefit your operations, be sure to consult with Six Star Bulk Bag.